Optimizing Efficiency: Picking the Right Aftermarket Construction Parts for Your Fleet

Optimizing Efficiency: Picking the Right Aftermarket Construction Parts for Your Fleet

Blog Article

Maximize Performance: The Benefits of Making Use Of Aftermarket Parts for Heavy Equipment

In the world of hefty equipment upkeep and optimization, the utilization of aftermarket parts has arised as a calculated option for many market specialists. As sectors continue to look for means to boost the performance and toughness of their heavy equipment, the conversation bordering the advantages of aftermarket parts becomes significantly compelling.

Cost-Effective Solution

An affordable method to maintaining hefty equipment is by choosing for aftermarket parts, which provide a cost-efficient service without compromising top quality. Aftermarket parts are produced by third-party firms as substitutes for original devices supplier (OEM) parts.

Variety of Options

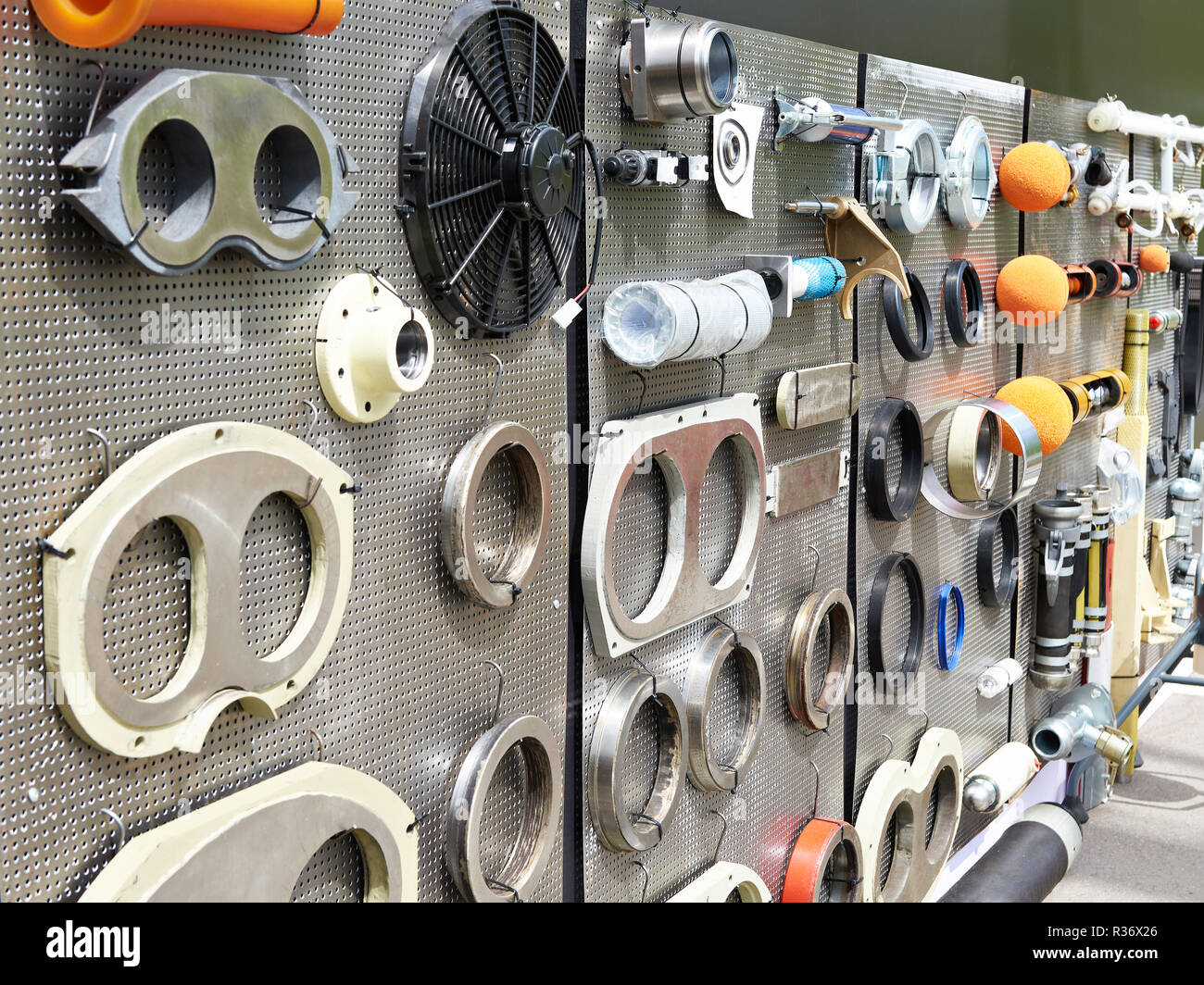

In addition, the schedule of aftermarket components from multiple vendors and producers creates an open market that drives advancement and quality renovation - aftermarket construction parts. This competition advantages businesses by providing them accessibility to highly sophisticated components that may not be available from initial devices suppliers (OEMs) By having a vast array of aftermarket options to choose from, companies can optimize the efficiency, effectiveness, and long life of their heavy equipment while maintaining prices controlled

Improved Efficiency and Performance

Enhancing heavy equipment efficiency and efficiency via the utilization of aftermarket components is a strategic method that lots of companies are significantly adopting. By including aftermarket components specifically made for hefty equipment, firms can dramatically boost the general functionality and productivity of their equipment. Aftermarket components typically offer sophisticated technology and boosted materials compared to original tools maker (OEM) components, leading to enhanced performance degrees.

One key facet of aftermarket parts adding to enhanced performance is their ability to attend to particular issues or weak points in the original machinery layout. This targeted strategy can lead to much better general performance, decreased downtime, and raised functional performance. Additionally, aftermarket components are regularly engineered to offer far better longevity and longevity, further enhancing the equipment's efficiency over an extensive duration.

Furthermore, aftermarket parts can aid optimize the machinery's gas usage, causing cost financial savings and environmental benefits. By fine-tuning the devices's components, services can attain higher levels of performance, equating into enhanced find more productivity and sustainability in the future. In verdict, leveraging aftermarket parts to boost hefty machinery performance and effectiveness can offer a competitive side in today's demanding commercial landscape.

Increased Modification Opportunities

Structure upon the improved performance and performance achieved with aftermarket parts, hefty machinery operators can currently discover boosted customization opportunities to more enhance their tools. By including aftermarket parts that cater to specific needs, drivers can adjust their machinery to carry out tasks much more effectively and effectively. In addition, aftermarket components offer the versatility to adjust different aspects of the equipment, such as hydraulic systems, controls, and safety attributes, enabling for a customized approach to tools optimization.

Extended Equipment Life Expectancy

By making use of aftermarket components specifically designed for hefty machinery, equipment proprietors can dramatically extend the life of their devices (aftermarket construction parts). These parts can improve the performance of hefty machinery, leading to smoother procedures and reduced wear and tear on important elements.

Regular maintenance and timely replacement of worn-out components are essential methods to prolong the life-span of site link hefty machinery. Aftermarket parts supply a cost-efficient option contrasted to original tools supplier (OEM) parts, allowing tools proprietors to preserve their equipments at a lower cost without jeopardizing quality. In addition, the schedule of a variety of aftermarket parts makes it less complicated to discover suitable replacements for numerous equipment models and brand names, even more sustaining the durability of hefty devices. Inevitably, purchasing aftermarket parts can result in significant price financial savings and raised efficiency by keeping heavy equipment functional for longer durations.

Conclusion

In verdict, making use of aftermarket components for heavy machinery supplies a cost-efficient option with a variety of choices that can boost efficiency and performance. These parts likewise enable boosted personalization possibilities and can add to prolonging the lifespan of the machinery. In general, integrating aftermarket parts right into heavy equipment upkeep and fixing strategies can optimize efficiency and maximize operational results.

Aftermarket parts are manufactured by third-party business as replacements for original devices supplier (OEM) components. Furthermore, aftermarket parts come in different cost functions, varieties, and high qualities, allowing companies to choose the components that finest match their budget plan and performance requirements.

Aftermarket components often use innovative important site modern technology and enhanced products compared to initial devices manufacturer (OEM) components, leading to enhanced performance degrees.

Report this page